|

Dongguan Yaxun Electronic Hardware Product Co., Ltd

|

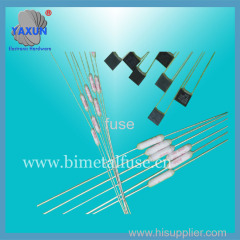

AUPO NEC RH Emerson thermal fuse

| Price: | 0.02 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

high precision operating temperature, fusing action is reliable, not premature or delayed blown;

The thermal fuse is a non-resettable, one-time overheat protection element, and the current fuse is a one-time overcurrent protection element. Series connection in a variety of electrical power input, when the use of household appliances in the abnormal temperature changes, or temperature out of control lead to excessive temperature rise, the thermal fuse can quickly cut off the circuit to avoid the occurrence of fire.

Commonly used in: hair dryer, iron, rice cookers, electric stoves, transformers, motors, drinking fountains, coffee pots and so on.

We not only related to the product structure and technology, more in-depth to the core of the product - Fuse materials development and application, such as fusible alloy wire, lead antimony alloy wire, organic mixture and so on. To provide you with one-stop from the rapid proofing to small batch production services. Please contact our professional team, let us come for you to achieve all the technical requirements.

What Is A Thermal Fuse?

Thermal fuse, is overheat protection components, also known as temperature fuse or Thermal Cutoff (GB GB1616.1-2013), widely used in electrical overheating protection.

The temperature sensing portion can be divided into:Fusible alloy wire and organic particle type temperature fuse, after fusing once cut off the current, non-recovery type thermal fuse.

Features Of Thermal Fuses

In Yaxun can provide a full range of thermal fuses, from your first consultation message to the final product delivery, you can get our engineers and sales staff professional, personalized service.

(1) high precision operating temperature, fusing action is reliable, not premature or delayed blown;

(2) good thermal stability, long-term in a high temperature state will not get out of control;

(3) load current up to 20A, it can be adapted to use a large current household appliances;

(4) the shell is not charged, the use of safe, easy to install;

(5) low prices, to adapt to mass production.

(6) temperature response speed;

(7) small size, easy to install.

(8) Structural accurate, resistance to vibration, impact resistance, applicable to household appliances, industrial circuit overheating protection;

Structural Classification Of Thermal Fuse

organic type metal shell temperature fuse is a combination, the composition of the structure are:

1. Pin (A), 2. Sealed resin, 3. Insulating ceramic, 4. Fine spring, 5. Star reed, 6. Coarse spring, 7. wafer, 8. temperature sensing block, 9. The housing, 10 Pin (B).

When the temperature insurance is in normal operation, the current flows from the left lead to the sliding contact and flows through the metal housing to the right lead. When the external temperature reaches the predetermined temperature, organic matter can melt melt, the compression spring will become loose. That is, spring expansion, sliding contact (slidingcontact) and the left side of the separation. The circuit will cut off, the current between the sliding contact and the left lead is cut off. the temperature fuse will fail and can not be used again.